Campylobacter in poultry

Food safety is an absolute priority for Co-op and we are determined to tackle Campylobacter. How will we do this? By working together with our farmers and suppliers to reduce the incidence of Campylobacter. We have been keen supporters of the initiatives the FSA (Food Standards Agency) have driven to combat Campylobacter.

Welfare matters

All Co-op chicken is 100% British, sourced from farms across the UK and run by farmers who are all members of the Co-op Chicken Farming group. Animal welfare is a priority to us and important to the way we run our business. It’s the Co-op way to look after the animals in our care, within a transparent and monitored supply chain.

On Farm

Since 2011, we have established seven dedicated farming groups which includes our chicken group. These groups give us a really clear understanding and oversight of our supply chain which means we can work closely with our farmers to ensure best practices are always in place. These include animal welfare, good husbandry practices, biosecurity and food safety as well as improving the overall quality of the product. We are continuing to work collaboratively with our British farmers and suppliers to reduce the incidence of Campylobacter in chickens.

To reduce Campylobacter on farm we have implemented excellent barrier biosecurity controls. For example, external foot wear and footwear from neighbouring sheds are segregated to maximise biosecurity and reduce contamination risk. We have implemented increased biosecurity training and audits within the Co-op Chicken Farming Group Farms.

We continue to incentivise our farmers to meet our targets and adhere to best practice on biosecurity, awarding farms, which meet our targets for a range of criteria, including tackling campylobacter.

Throughout the supply chain

Co-op continues to lead the way in working with suppliers to implement new measures while also investing to find a long-term solution.

We have implemented, and continue to develop, a number of initiatives to reduce Campylobacter across our supplier processing sites including double scalding, blast surface chilling, introducing Campylobacter subject experts at each site and increasing the focus on hygiene.

Blast surface chilling and double scalding are techniques which are designed to reduce campylobacter levels on the surface of the chickens. One uses low temperature to kill the bacteria, the other heat. Since implementing these measures our tests show we have reduced Campylobacter to within FSA agreed targets.

In your home

On our chicken packaging and in our stores, we encourage consumers not to wash raw chicken prior to cooking as this can help spread bacteria. We also advise that, after handling raw chicken, customers wash hands and utensils thoroughly. The two important factors to reduce the risk of Campylobacter in the home are good kitchen hygiene and making sure the chicken is cooked all the way through.

Industry Campaign

Co-op were one of the first retailers to sign up to be part of the Foods Standards Agency’s ‘Acting on Campylobacter Together’ (ACT) campaign. The joint aim was to rapidly introduce and share the best workable and available technologies and techniques in food production and across the supply chain.

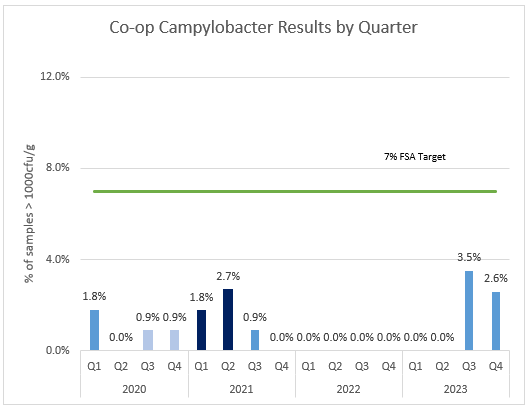

The FSA started the Campylobacter retail survey in 2014 sampling from nine retailers and publishing results showing % of chickens with incidence of Campylobacter at highest contamination levels (>1000cfu/g) . By the beginning of 2017 the overall results were showing a significant reduction in the percentage of chickens with high levels of Campylobacter from 20.3% (July 2014 – February 2015) to 7% with highest contamination levels (August – December 2016).

Heather Hancock, Chairman of the Food Standards Agency, said:

“The challenge we set of reducing the number of people who get ill from campylobacter has been achieved. In the absence of any other clear indicators, we can reasonably say that the work that we and the food industry have done from farm to fork has given us this really positive result for public health.

“This has been achieved by working with the industry to tackle this difficult problem and raising consumer awareness. We commend the efforts of the larger retailers and the major processing plants who supply them, all of which have shown significant improvement and many have achieved the target we set to reduce the highest levels of campylobacter. They have invested a lot of effort and money into interventions to tackle the problem.

Extract taken from the Campylobacter News Story 13.03.17

Our Results

From January 2017, food retailers have published our own Campylobacter test results for fresh chicken, in collaboration with the open data scheme on Campylobacter with the Food Standards Agency.

Co-op results for Q3 2023 show 2.6% of our chickens sampled had contamination at levels greater than 1,000 cfu/g. The FSA target is for a maximum of 7% of our chicken to be at the highest levels. Our testing shows that the initiatives we have introduced in collaboration with our suppliers continue to reduce highest contamination levels to within the industry target. We are continuing to work in partnership with our supply chain to reduce Campylobacter levels in poultry.

What exactly is campylobacter?

It's the most common form of food poisoning in the UK, with four out of five cases coming from poultry. Symptoms (including abdominal pain, diarrhoea, fever and vomiting) usually develop two to five days after eating the contaminated food. Most people recover without treatment within two to five days.

Can I see Campylobacter?

You can’t see, smell or even taste Campylobacter.

Is there a real risk of my family getting food poisoning from chicken?

If you and your family practice good hygiene when handling raw chicken then there should be no risk.

However, if you are concerned, we have a tasty chicken range in store, which you don't have to touch at all. You simply put the chicken, in its bag, straight in the oven. All the hard work has been done – some have also been flavoured with herbs and spices.

We eat chicken a lot but now I’m worried about touching it. Is it ok to touch raw chicken?

Yes, it’s absolutely fine to touch raw chicken, so long as you wash your hands and any kitchen utensils, chopping boards and surfaces properly afterwards. Just don’t wash the chicken itself (see below for reasons why). Use a good surface cleaner on surfaces that the chicken has touched, and wash utensils, chopping boards and hands in warm soapy water. It is a good idea to have a separate chopping board for raw meat to avoid cross-contamination.

How should I store raw chicken?

Make sure you put any leftover raw chicken in a sealed, clean container on the bottom shelf of the fridge where it can't touch or drip on to other foods. And eat it within the use-by date on the packaging.

Why should you not wash your chicken before cooking it?

Contrary to popular belief, washing raw chicken doesn’t remove bacteria – only cooking kills it properly . When washing chicken, the water can splash, potentially spreading bacteria from the chicken onto hands, kitchen surfaces, clothes and cooking utensils.

What is the safest way to cook chicken?

If you practice good hygiene when handling raw chicken (see tips above) and put the chicken directly onto a roasting dish or into a pan, without washing it, then cooking chicken is safe. Just follow the on-pack instructions to find out how long to cook it for and at what temperature setting. And make sure you check the meat is cooked through before serving (see tips below)

How do you know when chicken is cooked properly?

To check that chicken is cooked properly, simply cut into the thickest part of the meat (this is the shoulder on a whole chicken) and make sure the juices are running clear, with no pink meat or bloody juices visible. Then you can serve it up and enjoy!

Why can’t you make all your chicken campylobacter free?

We’ve made great progress in reducing Campylobacter but it is a naturally occurring bacteria and is difficult to completely eliminate. However, along with the FSA, industry and suppliers, we continue to put in place measures to reduce the incidence and invest in research and trials with the aim of eliminating Campylobacter on farms and throughout the supply chain.